How to Evaluate the Quality and Price of a Mascot Costume?

Choosing the right mascot costume is crucial for brand representation, performance, and

longevity. However, many buyers struggle to balance quality and budget. This

guide breaks down the key factors to help you make an informed decision—from

materials and craftsmanship to design complexity and budget management.

1. Durability Depends on Materials

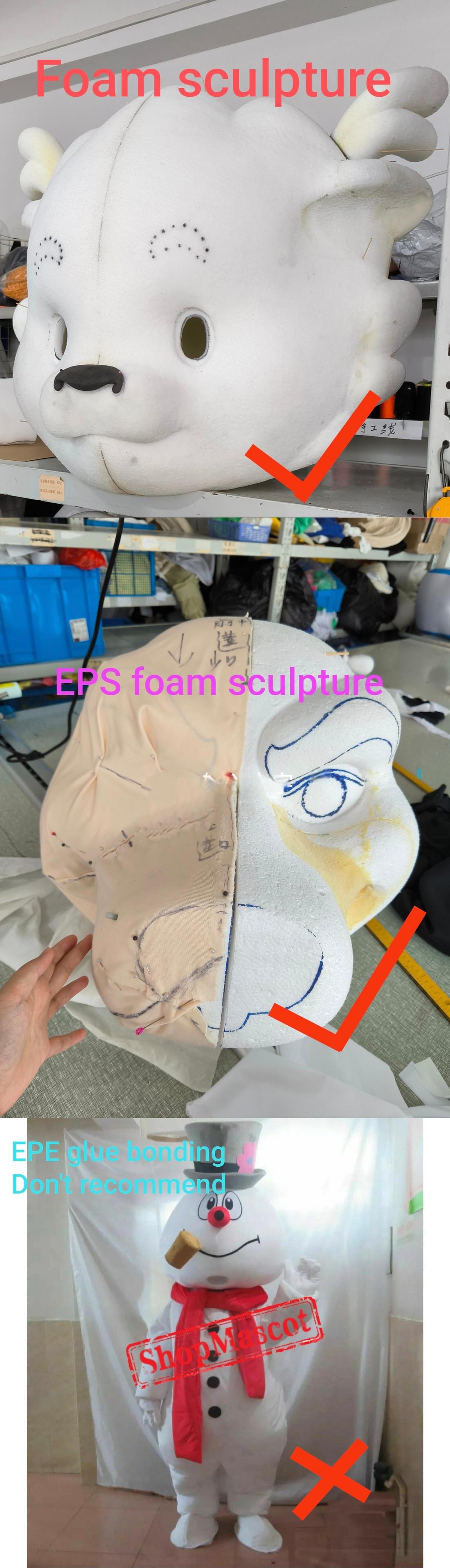

Head Structure: Firmness and Shape Retention

The headis the most critical part of a mascot costume. It must be sturdy, well-shaped,

and visually appealing. Here are the common materials used:

· High-Density Foam/sponge:

o Ideal for creating sharp,defined features (e.g., animal snouts or character eyes).

o Light weight, making it comfortable for performers.

o Prone to damage if mishandled.

o Suitable for mascots requiring frequent transport or rough usage.

· High-Density EPS Foam:

o Offers excellent shock absorption and resistance to deformation.

o Often combined with foam for complex designs.

· Avoid EPE Materials:

o EPE (Expanded Polyethylene) ischeap but lacks durability.

o Easily deformed under pressure,leading to a shorter lifespan.

Image 1: Comparison of foam vs. sponge head structures vs. EPE material deformation example

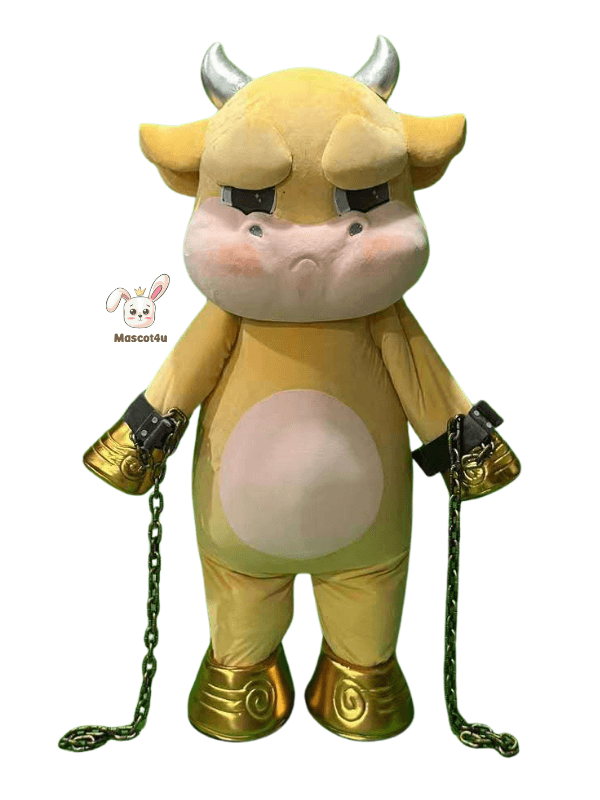

Premium Option: Carbon Fiber Molded Heads

For mascots based on human characters or designs requiring precise facial features

and skin tones, carbon fiber molds are the gold standard:

· 100% design accuracy with lifelike details.

· Extremely light weight and durable,resistant to drops and impacts.

· High upfront cost due to custom molding—ideal for bulk order or high-budget projects.

Image3: Carbon fiber mascot head with detailed facial features.

Alternative: Inflatable Mascots

Forlarge, simple-shaped mascots (e.g., giant balls or basic objects):

· Lightweight and portable (comeswith a built-in battery and fan).

· Comfortable to wear but limited inreplicating intricate designs.

Image4: Inflatable mascot in action.

Material Price Comparison:

Carbon Fiber > High-Density Foam > High-Density EPS Foam > EPE

Fabric Selection: Realism and Functionality

The outer fabric determines the mascot’s appearance and durability:

· Long-Pile Plush: Best for animal mascots(e.g., bears, tigers) to mimic fur.

· Short-Pile Plush: Suitable for printedpatterns or object-based designs.

· Custom Fabrics: Use realistic materialsfor accessories like denim for jeans or nylon for backpacks to enhance authenticity.

*Image 5:Long-pile vs. short-push fabric samples.

*Image6: Custom fabric accessories (denim, caps).

2. A esthetics Lie in the Details

Subtle craftsmanship differences can significantly impact the mascot’s lifespan and

brand image. Pay attention to:

· Seam Construction:

· Poorly stitched seams canunravel during performances.

· Reinforced stitching ensureslongevity.

*Image 7: Well-stitched vs. poorly stitched seams.

Facial Features and Vision:

· Eyes, nose, and mouth shouldbe three-dimensional and symmetrical.

· Vision holes must be clear andstrategically placed for performer safety.

*Image 8: Mascot with Defined facial features and clear vision holes.

*Image 9: Mascotwith uneven facial features.

Accessories Quality:

· Buttons, belts, or emblemsshould be securely attached and finely crafted.

*Image 10: Detailed mascot accessories (buttons,patches).

*Image 11: Low-quality accessories example.

3. Budgeting Based on Design Complexity

The complexity of the design is the most significant cost driver. Instead of

compromising on materials or craftsmanship, simplify the design to fit your budget.

Pro Tip: Work with experienced mascot designers (likeMascot4u) to refine your design early—ensuring cost efficiency without sacrificing quality.

4. How to Choose the Right Mascot for Your Budget

For High-Budget Projects:

· Prioritize premium materials (e.g., carbon fiberheads, reinforced stitching).

· Provide detailed requirements upfront (fabric type, accessory specs,packaging).

For Limited Budgets:

· Simplify the design (e.g., fewer colors, minimal accessories).

· Discuss cost-saving options with your mascot maker (e.g., usingsponge instead of carbon fiber).

5-Step Selection Checklist:

1. Confirm Materials: Choose based on durability needs

2. Optimize Design: Let the mascot maker refine the design for cost efficiency.

3. Request Craftsmanship Details: Ensure transparent production standards.

4. Clarify Packaging &Shipping: Avoid damage during transit.

5. Compare Quotes: Balance price with quality guarantees.

Final Thoughts

A well-made mascot costume not only enhances brand visibility but also withstands

the test of time. By understanding materials, craftsmanship, and design trade-offs, you can invest in a mascot that delivers both quality and value.

Need help creating a high-quality mascot within your budget? Contact Mascot4u’s design

team for expert guidance